Did you know that over 70% of India’s precision components in automotive and aerospace are now made using CNC machining? From Tata Motors producing high-performance automotive parts to ISRO building aerospace components with micron-level accuracy, CNC machining has quietly become the backbone of Indian manufacturing.

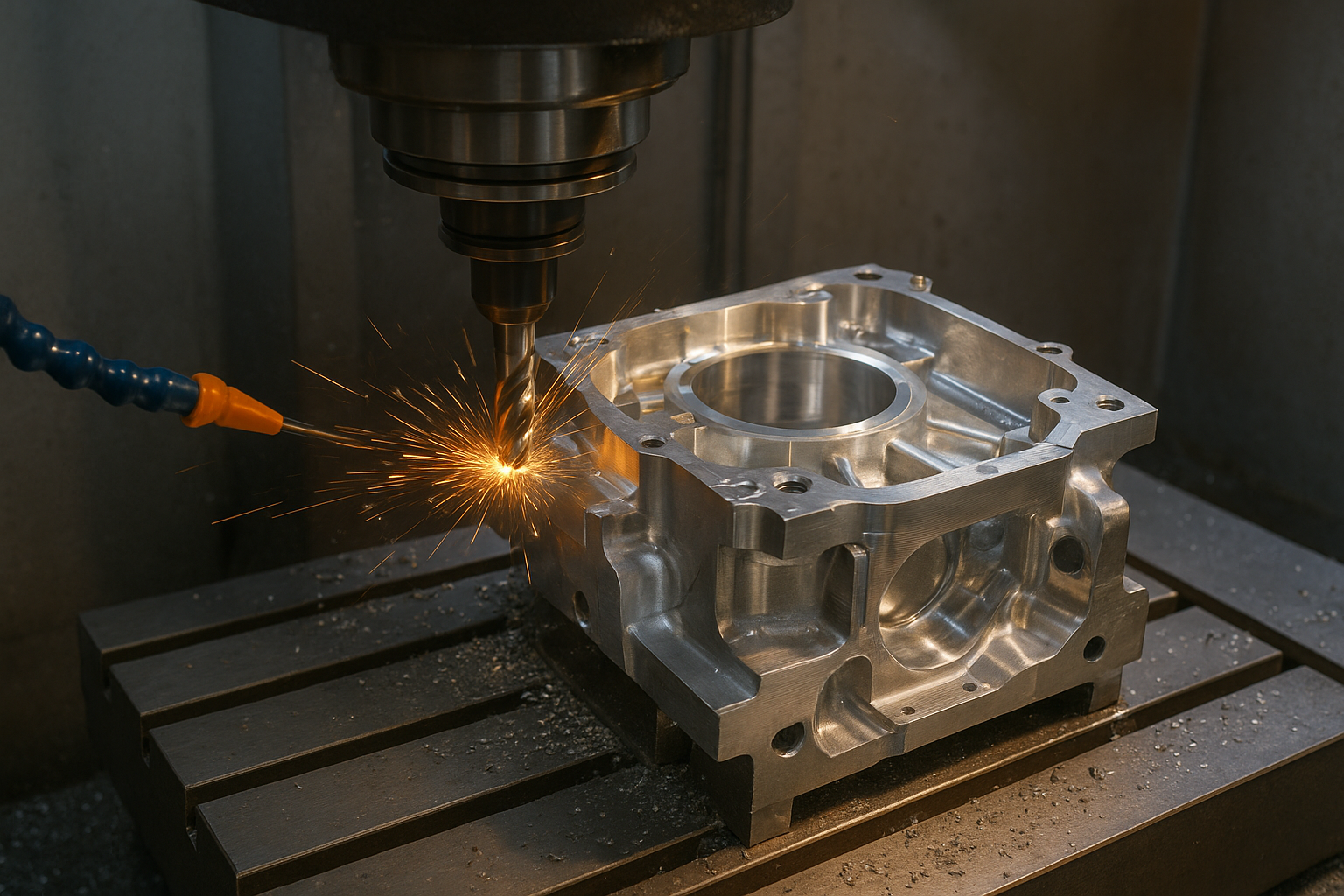

But it’s not just about machines cutting metal—it’s about a nation scripting its future. Every CNC-milled engine block, every turbine blade, and every satellite part is a step toward securing India’s place as a global leader in innovation and self-reliance.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control tools like lathes, mills, routers, and grinders. Unlike manual machining, CNC delivers:

This precision isn’t just technical brilliance—it’s the foundation of trust. When an ISRO rocket takes flight or when an EV battery keeps families moving, that confidence is built on CNC machining.

Why CNC Machining is Crucial in Indian Manufacturing

|

Feature |

Manual Machining |

CNC Machining |

|

Accuracy |

Dependent on operator skill |

Micron-level precision |

|

Speed |

Slow, labor-intensive |

Fast, automated cycles |

|

Repeatability |

Inconsistent |

Highly repeatable at scale |

|

Complexity of Designs |

Limited |

Handles complex geometries |

|

Cost Efficiency |

Higher over time |

Lower waste, reduced rework |

This leap isn’t just technical—it’s symbolic of India’s leap from dependency to self-reliance and innovation leadership.

Applications of CNC Machining in Indian Industries

Case Studies: CNC Machining in Action

Case Study 1 – ISRO’s Chandrayaan Mission

CNC machining produced lightweight, high-strength components for the Chandrayaan lunar missions. Each CNC-cut part was not just metal—it was India’s ambition touching the moon.

Case Study 2 – Tata Motors EV Development

Tata’s Nexon EV development involved CNC-machined battery housings, enabling faster prototyping and reliable production. With CNC at its core, India is accelerating toward a greener tomorrow.

Technologies Powering CNC Machining in India

These technologies are not just tools; they are the enablers of India’s march toward Industry 4.0 leadership.

The Future of CNC Machining in India

CNC machining is evolving to align with Industry 4.0, sustainability, and global competitiveness:

By 2030, CNC machining will not just be at the heart of India’s advanced manufacturing ecosystem—it will be the heartbeat of India’s global industrial leadership.

Conclusion

CNC machining has transformed Indian manufacturing by combining precision, scalability, and flexibility. From Tata Motors’ EVs to ISRO’s spacecraft, CNC technology ensures that India not only competes at a global level but also secures its rightful place as a leader in innovation and engineering excellence.

But CNC is more than machines and code—it’s about empowering people, industries, and the nation. Every component manufactured with CNC represents India’s growing strength, resilience, and ambition to become a global manufacturing powerhouse.

If you’re ready to harness the power of CNC machining for your business and be part of India’s journey toward global leadership, partner with us at Brick & Byte. Together, we can transform your ideas into world-class precision products.

FAQs

Q1: What is CNC machining and why is it important in India?

CNC machining is a computer-controlled manufacturing process that ensures precision and scalability. In India, it drives innovation in automotive, aerospace, defense, and EV manufacturing.

Q2: How does CNC machining reduce costs?

By minimizing material waste, lowering rework, and automating production, CNC machining offers greater cost efficiency compared to manual methods.

Q3: Which industries in India benefit most from CNC machining?

Automotive, aerospace, defense, medical devices, and energy sectors are the largest adopters of CNC machining solutions in India.

Q4: What’s the difference between CNC and traditional machining?

CNC provides micron-level accuracy, repeatability, and speed, while traditional machining depends heavily on operator skill and is less scalable.

Q5: What is the future of CNC machining in India?

With AI, IoT, and digital twin integration, CNC machining will power India’s shift toward smart factories and Industry 4.0.